Broadband Electromagnetic Probe (BEM) identifies and measures the integrity of ferrous pipe walls

BEM is a main ferrous assessment tool and patented technology, effective for investigating cast iron, ductile iron and steel pipelines of all diameters. The technology identifies loss of metal as little as 1mm through corrosion, abrasion or graphitization. It also detects cracks and other flaws. BEM has been in operation for over 20 years with PPM partner, Rock Solid Pty. They have extensive experience with non-destructive assessment of cast iron and other ferrous piping.

Surveys through thick coatings and linings such as epoxy, cement mortar, plastic or concrete

Effective for eliminating unnecessary exposure to underground utility infrastructure

For pipes of any size from 110mm (4 inches) diameter upward to be investigated

A major advantage over alternative approaches such as ultrasonics

Effective for reducing installation costs

It can be used externally or internally

BEM PROJECT PROFILE

PIPELINE WALL CONDITION ASSESSMENT TOOL

Broadband Electromagnetic (BEM) probe measured wall thickness of gas pipeline prior to CIPL project.

CLIENT

NEW JERSEY UTILITY

LOCATION

WEST DEPTFORD, NJ

YEAR

2022

PIPELINE APPLICATIONS

The Flexible Array Scanning Tool (FAST) strips adjust to the pipe circumference and form a “blanket.” Inside each strip are sensors, antennae and cables that connect to the core processor.

Flexible Array Scanning Tool (FAST) External Ferrous Wall Condition Assessment

Ideal for external pipe wall condition assessments carried out on all types of ferrous pipelines to explore the integrity on pipe diameters from 2” and upwards. The pipe wall is scanned externally and pipe wall integrity is determined without interrupting the pipe flow or disrupting gas service.

The PIG (pipe inspection gauge) moves through the pipes via a tether or rod and takes three readings per section. It can handle up to 90 degree bends with a single point of entry

In-Line Internal Ferrous Wall Condition Assessment

Internal pipe wall condition assessments can been undertaken on any pipe from diameters 4” and upwards. Tunnels with diameters of greater than 20ft have been investigated. Continuous data can be recorded along extensive lengths of buried pipelines. Pressure pipelines require brief interruption of operation to gain access.

““BEM helps our customers with critical and strategic decision making regarding their pipeline replacement programs. The ability to investigate wall thickness and condition of the pipeline before committing capital or maintenance dollars pairs well with Starline cured- in-place lining technology for complete pipeline renewal.””

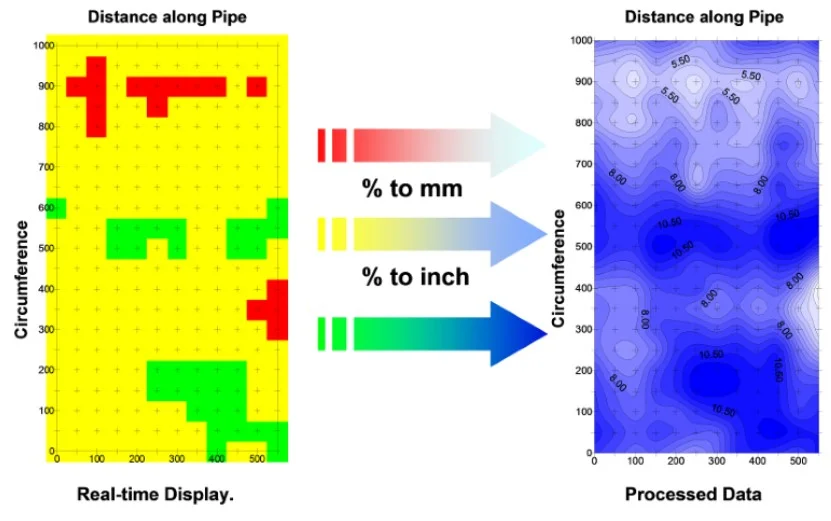

REAL TIME WALL THICKNESS RESULTS

Data is processed in a number of ways with initial readings and in depth data analysis. Green areas have 90% wall thickness in tact, while red indicates areas of concern.

Post survey data processing allows an easily understood and accurate presentation of results.