restoring pipelines at bridge crossings SAFELY & cost effectively

Replacing a pipeline structurally integrated into a bridge using traditional means is extremely expensive and in many cases impossible. Cured-in-place-Lining renews the pipeline and adds 100 years’ life without disturbing the bridge.

PPM reconditions and reinforce pipelines at bridge crossings without disturbing the bridge in any way.

why are pipelines on bridge crossings difficult to repair?

Pipelines run under a bridge or hang alongside the bridge and traverse the bridge’s abutment walls.

Corrosion is accelerated where the pipeline traverses the bridge abutment walls, and often causes leaks.

Excessive corrosion of the pipeline where the pipe enters the abutment wall of the bridge cannot be repaired without removing the pipe.

Engineering designs have to be submitted and approved to the bridge owner, DOT and city/county regulators.

Simple change in hangers can sometimes make the project a no-go. Hangers that support the pipeline need to be replaced with new hangers of approved designs, per owner’s SOP.

Starline Cured In Place Lining for bridge crossings realizes significant cost savings vs. traditional replacement

CIPL lining on a bridge crossing is far less expensive than replacing and in most cases is the only viable option. Leaving the pipeline in place and repairing using CIPL eliminates the problems of replacement.

Carbon Fiber Structural Reinforcement sleeves (SRS)

PPM’s SRS sleeves are made of a high strength carbon fiber laminate with a glass outer skin, and are installed robotically into the pipeline. The carbon fiber material bonds to the interior of the pipeline, and improves the pipe’s integrity at the position of the installation.

While each project is unique, carbon fiber SRS can save utilities as much as $500,000 per project, by preventing future corrosion and eliminating the need for costly additional excavations and pipe work.

projects

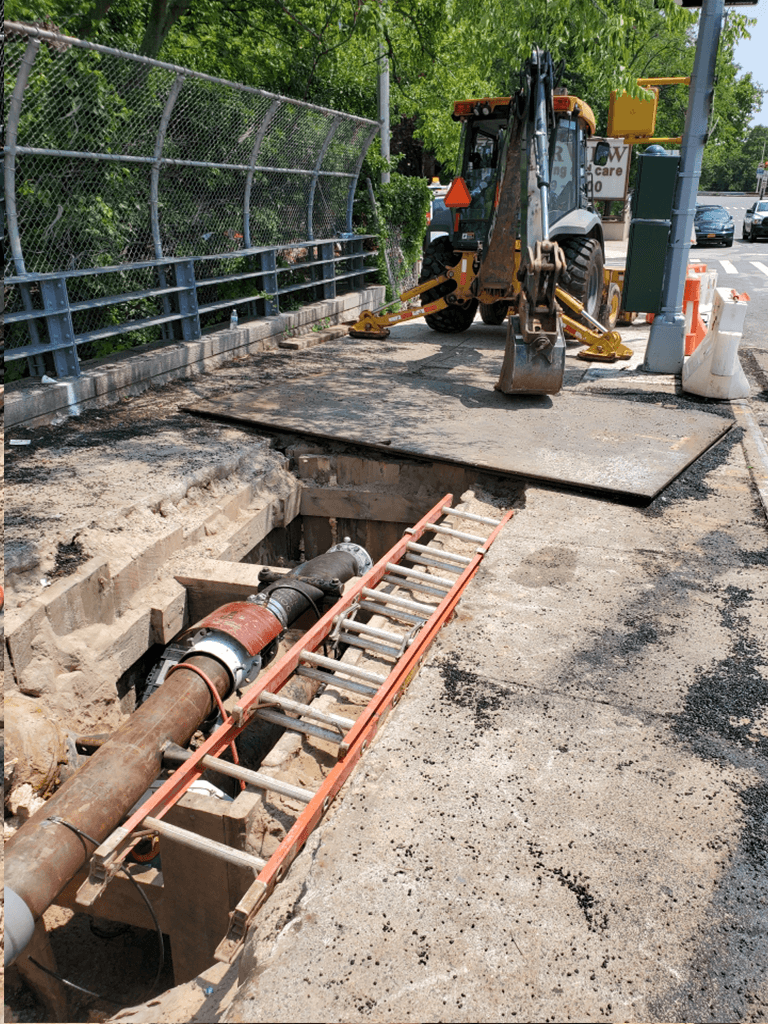

BRIDGE PIPELINE REPAIR AVOIDS COSTLY REPLACEMENT

CIPL eliminated leaks from a gas pipeline without disturbing the bridge

CLIENT

PSE&G

LOCATION

EAST ORANGE, NJ

YEAR

2020

CIPL TURNKEY SOLUTION FOR LEAK PRONE PIPE

Comprehensive construction contract proved to be an effective tool to remediate leak prone pipe.

CLIENT

NATIONAL GRID

LOCATION

QUEENS, NY

YEAR

2021

frequently asked questions

+Why are bridge crossing pipelines so complex, challenging and costly?

Utilities and contractors have limited access to repair bridges conventionally. The pipeline is hung under or alongside the bridge and traverses the bridge’s abutment walls, requiring contractors to use additional resources and equipment to safely work. A utility cannot just remove and replace the pipeline conventionally. In addition, pipelines at bridge crossings require multiple layers of approvals and restrictions from the owner, regulators and the DOT (Department of Transportation) before any traditional replacement can be completed.

Excessive corrosion of the pipeline is typical where the pipe enters the abutment wall of the bridge. The pipeline in the abutment walls cannot be repaired without removing the pipe, a costly and difficult process that affects the structure of the bridge. Utilities have many engineering challenges with traditional replacement, and rarely receive permission to disturb the structure of the bridge. Cured-in-place-lining at bridge crossings is a cost effective alternative.